Paper plants are featured by ever higher operating speeds, which is why it is always more important that cylinders and rotors in general are correctly balanced and free from vibrations.

Vibrations, whatever their origin, beyond a certain intensity can produce malfunctions of the systems, product faults, reduction in production speed, greater wear of components such as bearings and in the most serious cases even the breakage of journals or other components.

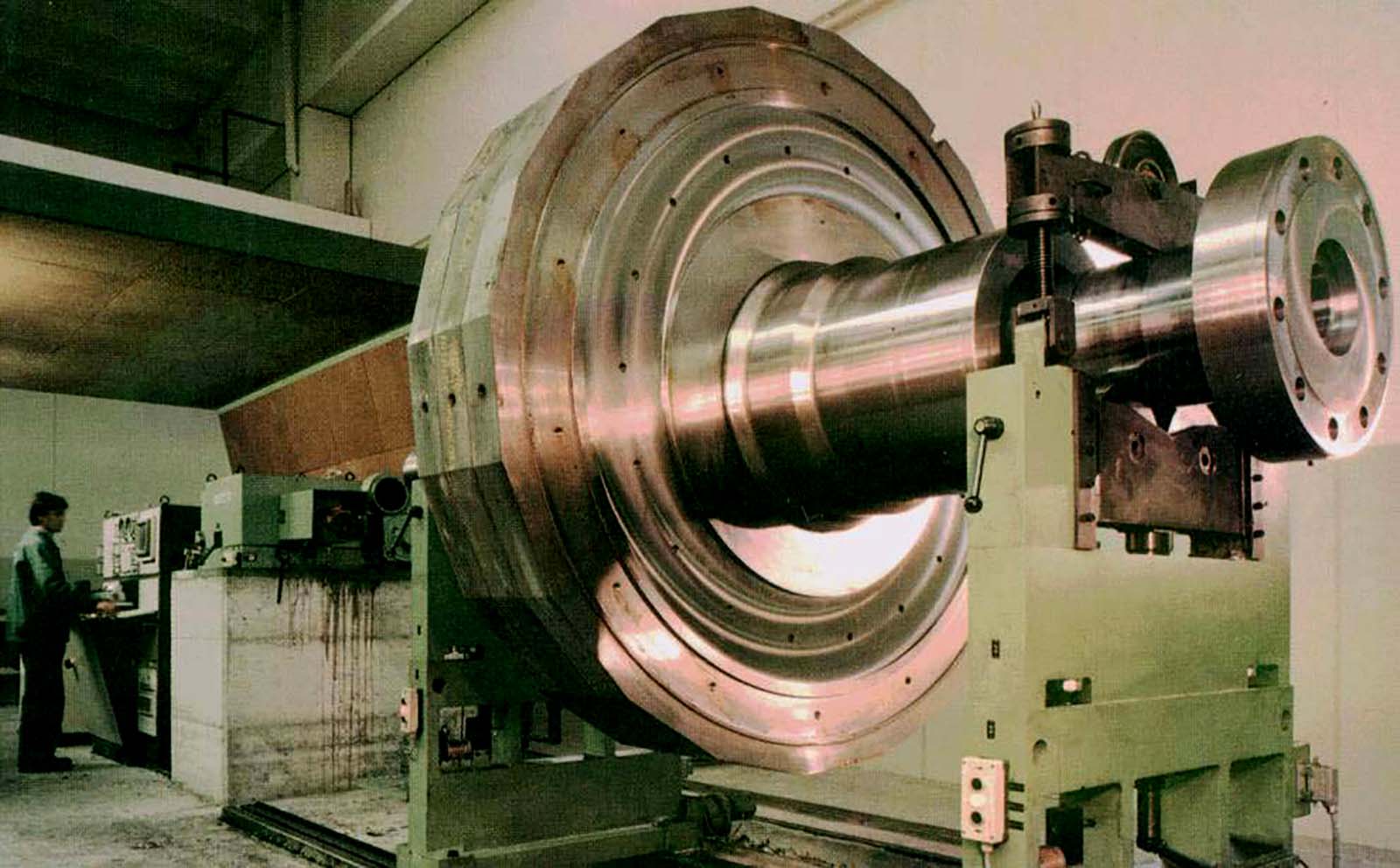

RIF offers its experience as well as large capacity balancing machines to solve the problems of unbalance and vibration of the cylinders.

However, a correct dynamic balancing control operation, to be called such, requires that all the parts making up the cylinder or rotor are geometrically in tolerance and perfectly clean. The machining, in particular the precision grinding, which for RIF represents the backbone of its technology, is in fact the first and most important correction phase of dynamic balancing.

The RIF service team is able to perform the following operations:

• Check / possible correction of the heads imbalance

• Check / possible correction of the dynamic runout at face center (this is essential in particular for cylinders with a high length / diameter ratio)

• Check / possible correction of dynamic balance of complete suction rolls

Where necessary, in particular when checking complex cylinders or rotors, equipped with their own supports and bearings, RIF is able to perform the vibration analysis, in order to verify the frequencies and establish which part is at the origin of any vibrations. with different frequencies compared to that of rotation.