RIF has made substantial investments in both machinery and technology in this sector and the satisfactory application feedback consolidates the results achieved and stimulates continuous steps in coating technologies and research of materials.

Thanks to the combination of specific knowledge in the field of thermal coating and the long experience in cylinders’ surface restoration, either inside our factory and directly at customer’s mills, this product line is proving to be one of the most interesting sectors in the market.

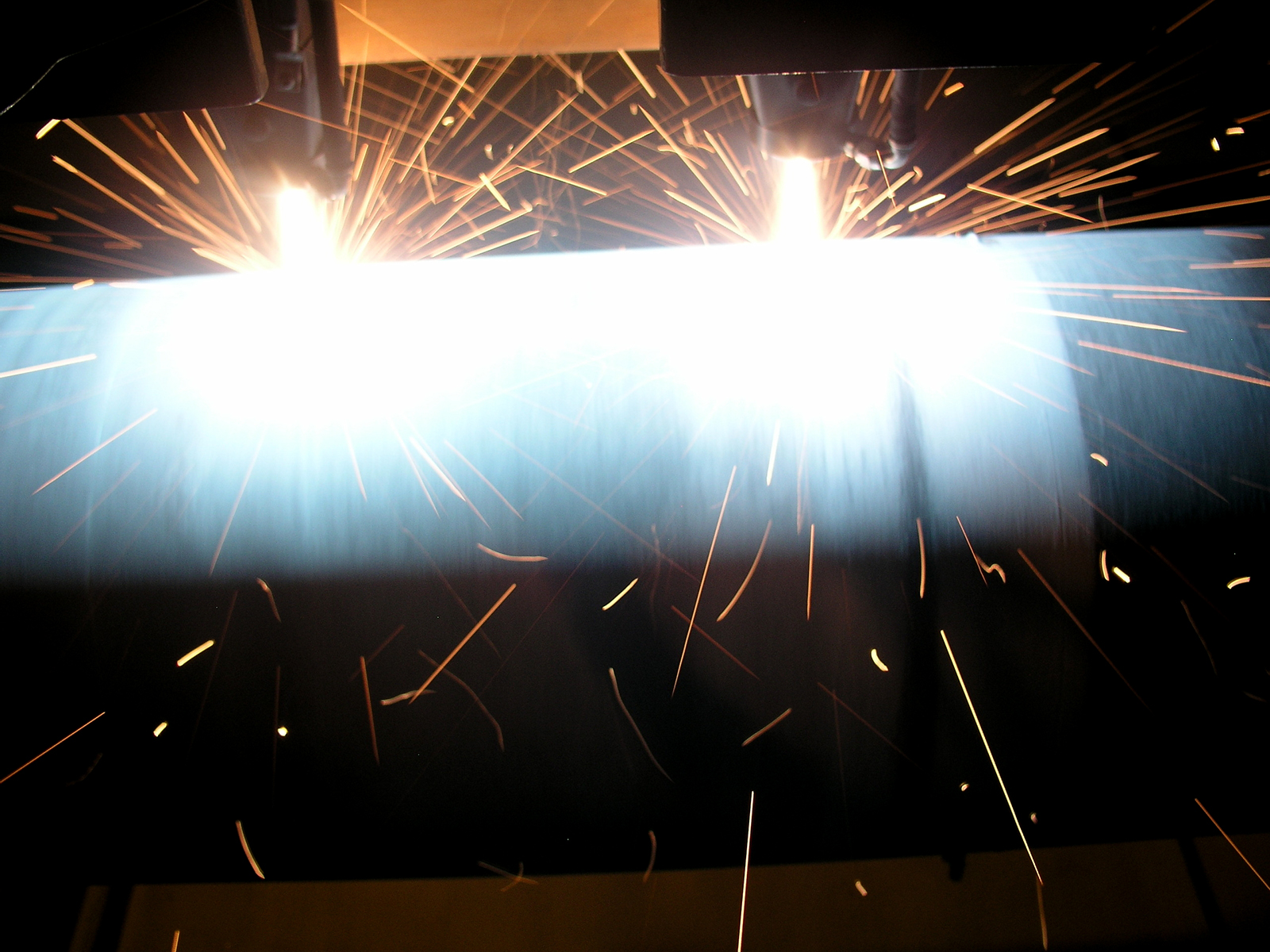

Carrying technologies used:

• Wire flame metallization

• Wire arc spray

• Plasma powder spray

• High velocity oxy-fuel (HVOF-HVAF)

Landfill materials:

• Special high chromium steels

• High molybdenum alloy

• Various anti-corrosive alloys

• Carbide / ceramic + Teflon composite overlays

• Special ceramics

• Special Bronze / Copper / Nickel alloys

Applications:

• Restoration of the journals pins

• Repairs of Suction Rolls shells seats and heads

• Repair of internal bearing seats of swimming rolls

• Spot repairs of Yankees and dryers

• Full-face coatings of Yankees and dryers with VARIHARD series coatings

• Wear resistant coatings for Pope reel rolls

• Anti-slip coatings for Rewinder backing rolls

• Non-stick and wear-resistant coatings for Dryer and Cooling Cylinders after size-press or coating stations

• Extremely high wear resistance coatings for Glazing rolls and Supercalender

• Wear-resistant and high-density ceramic coatings for guide cylinders

• Special ceramic coatings for wet section Press Rolls