At RIF we have at our disposal whatever is necessary for the complete design and manufacturing of rolls, in particular:

• A mechanical processing department managed by highly experienced staff

• A highly-skilled technical office perfectly integrated into the Company Quality System, managed by qualified technicians

• A series of dedicated machine tools, with large production capacities and equipped with a CNC control system

We manufacture cylinders and rotors for well-known industrial plants worldwide, based on their specific drawings and / or directly for end-users, taking advantage of our construction and design programs.

The experience in serving the paper industry for the refurbishment, repair, grinding and coating of used cylinders allows us to fully understand the purpose of use and needs of the various types of cylinders, therefore giving the utmost care in design, in choosing semi-finished products and in the realization of finished products.

Our Cylinder Construction Program includes:

• All type of guide rolls, smooth or profiled

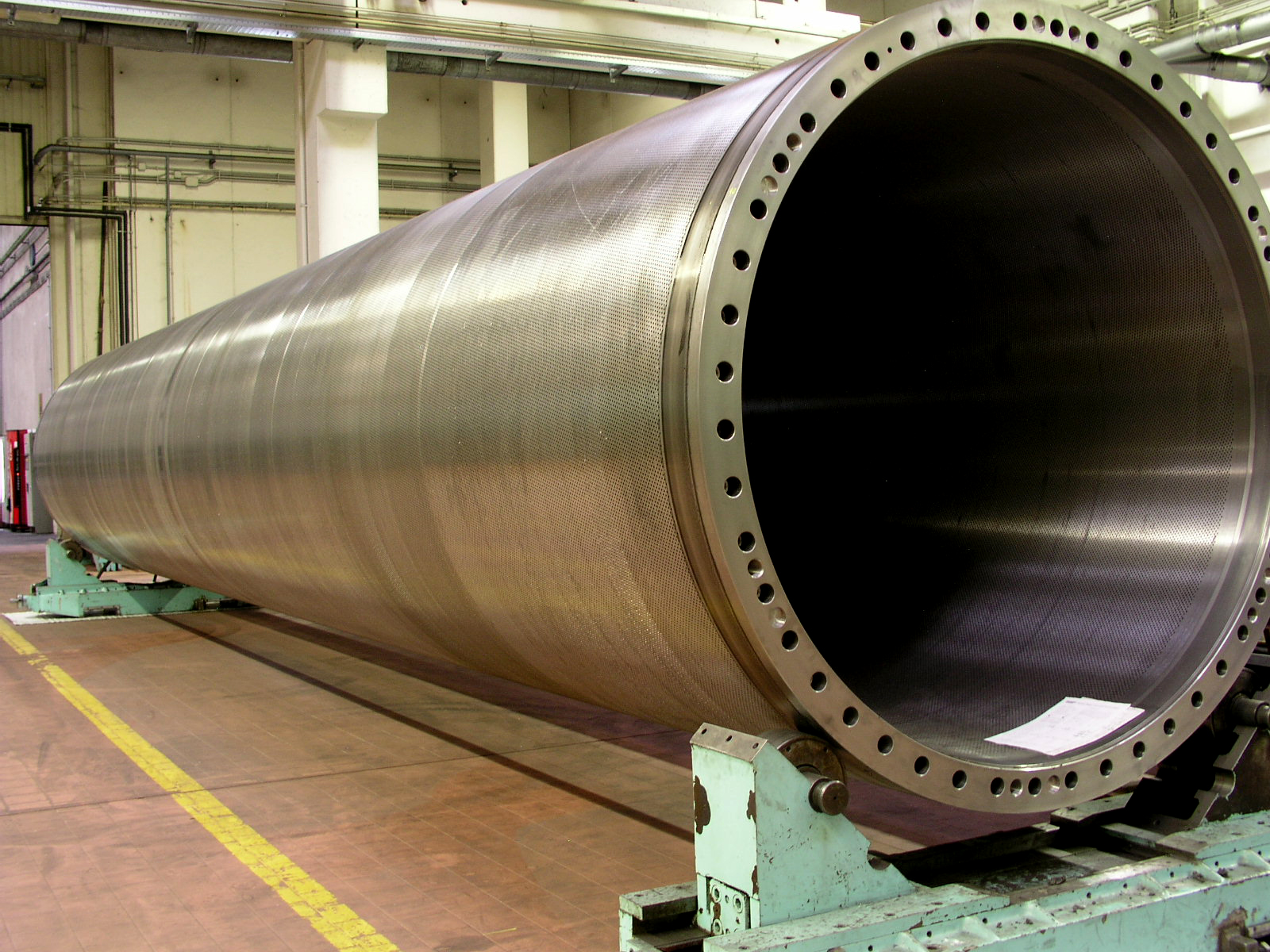

• Drilled rolls in the Drying Section

• Breast rolls and wire drive rolls

• Rewinder backing rolls, Pope rolls and Reel spools

• Wet press rolls and Yankee pressure rolls

• Size-Press rolls, Film-Press rolls and Coating cylinders

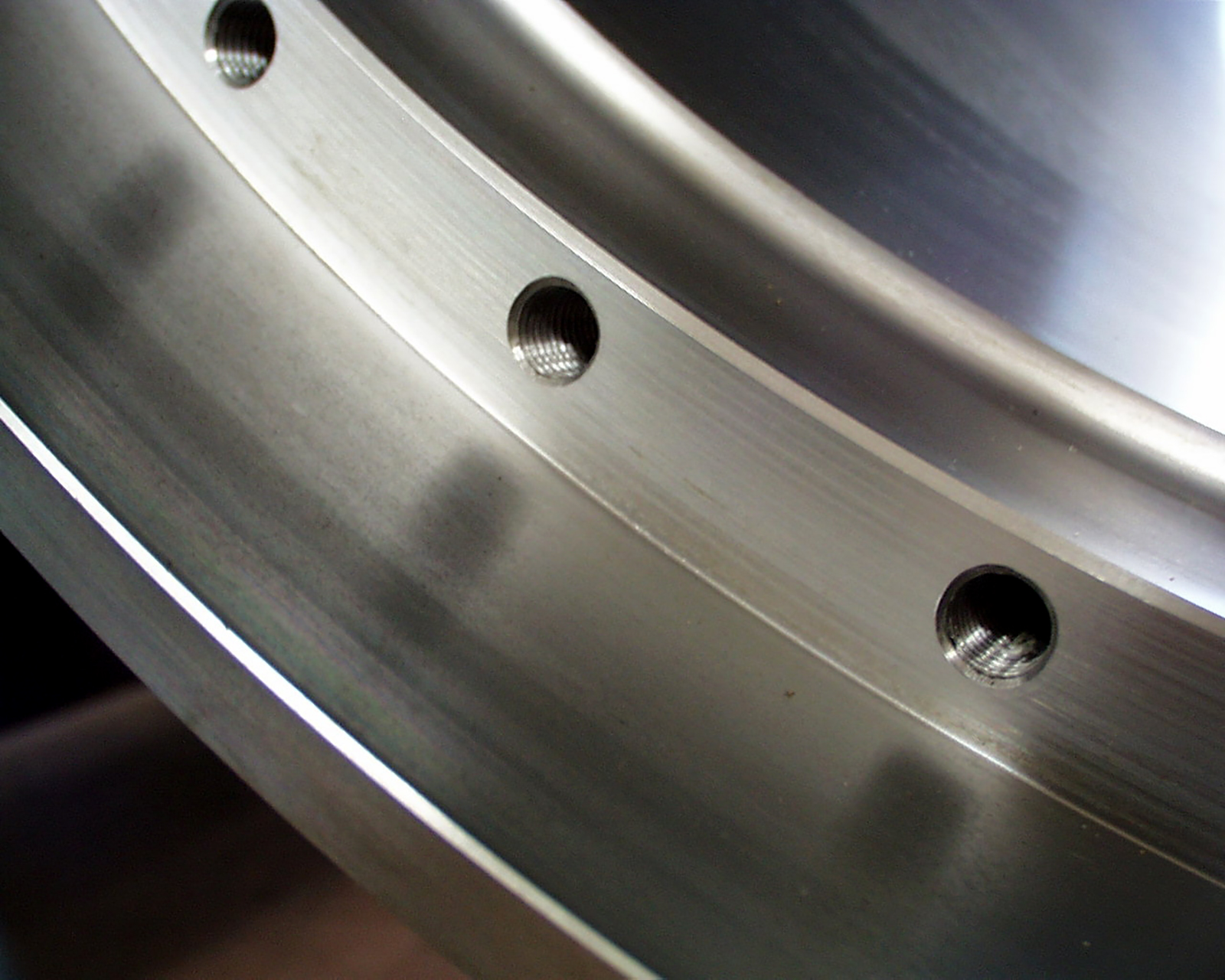

• Suction roll shells or complete suction rolls

• Bearing housings for all rolls

• Cooling cylinders for the Plastic Industry

• Cylinders, rotors, shafts for various industrial sectors

Design Program:

• Optimization of the construction project in order to reduce the weight of the cylinders and increase their operating speed

• Verification of the bending curves of the cylinder for the calculation of the crowns

• Computerized simulation of operating conditions

• Calculation of mechanical stresses

• Selection of suitable materials for rough pieces

• Calculation and design of the internal cooling system

• Check of the deflection curves of the roll for crown calculation

• Study of drilling patterns for the suction shells at the purpose to avoid compromising the mechanical resistance of the shell, eliminate the risk of “shadow marking”, improve dewatering and reduce the noise level