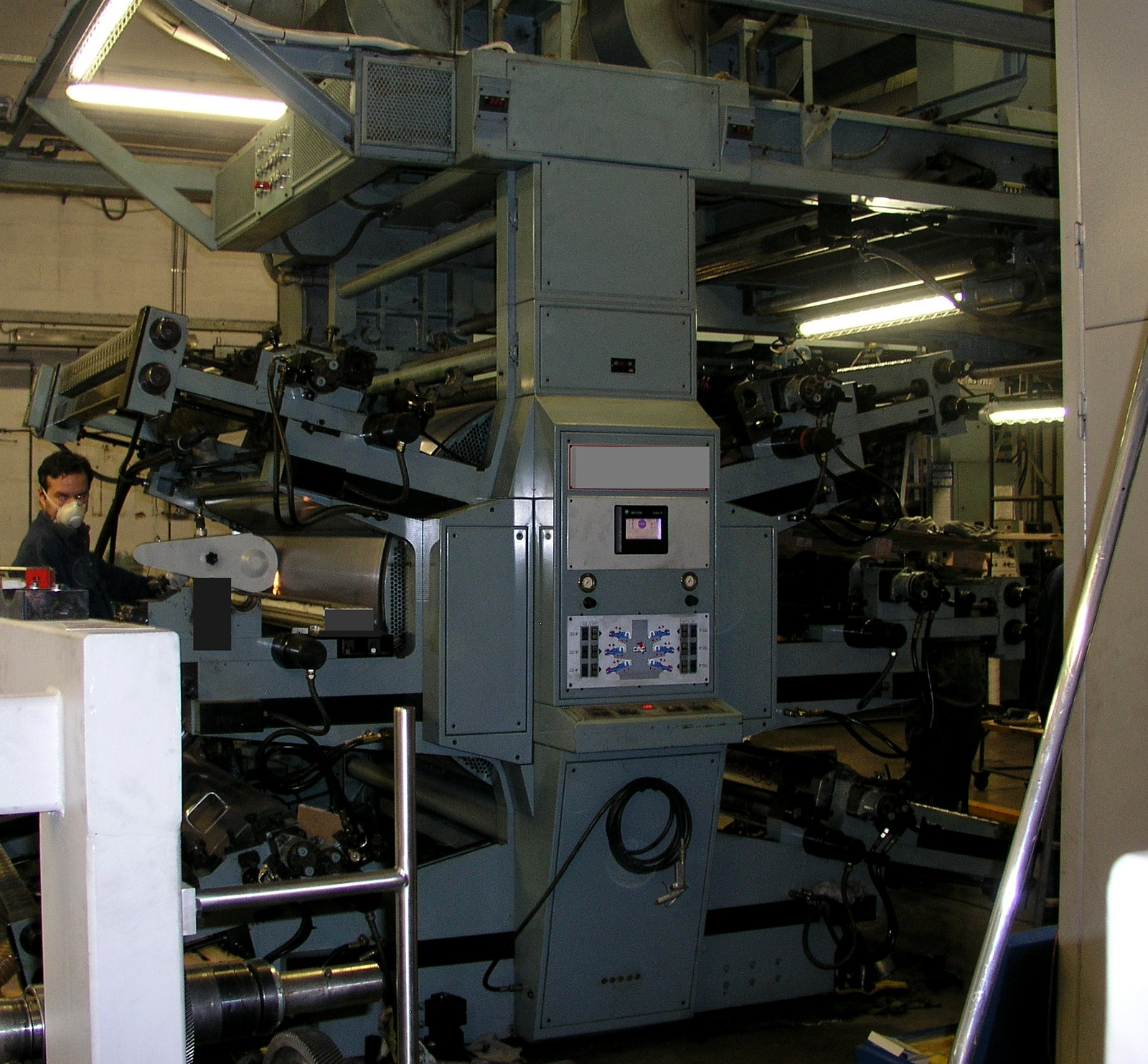

In addition to standardized on-site machining such as grinding and metallization, RIF’s team of expert technicians is able to perform tailor-made solutions in order to solve peculiar or unexpected problems happening at customers’ production plants; here below some examples:

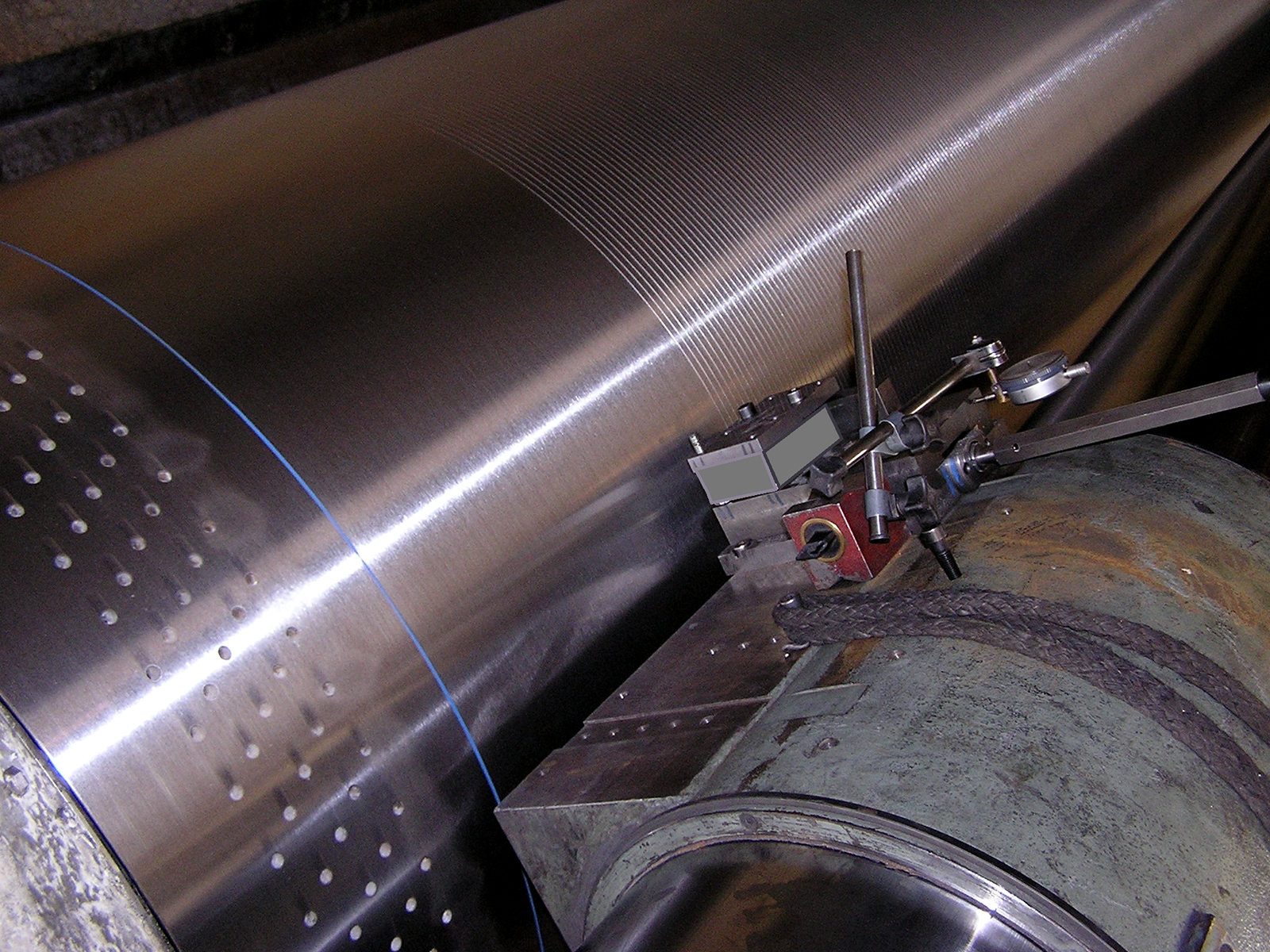

• Turning on journals / bearing seats of dryers and Yankee cylinders, with the cylinder stopped

• Metal coating / grinding of journals / bearing seats of dryers and Yankee cylinders

• Remaking of grooves on Pope cylinders

• Grinding of rolling seats of barking drums and similar

• Dedicated milling and boring operations

• Static or dynamic balancing

Other specialties of the “On-site” RIF Team concern trouble shooting / diagnostic services, for example:

• Vibration analysis on site

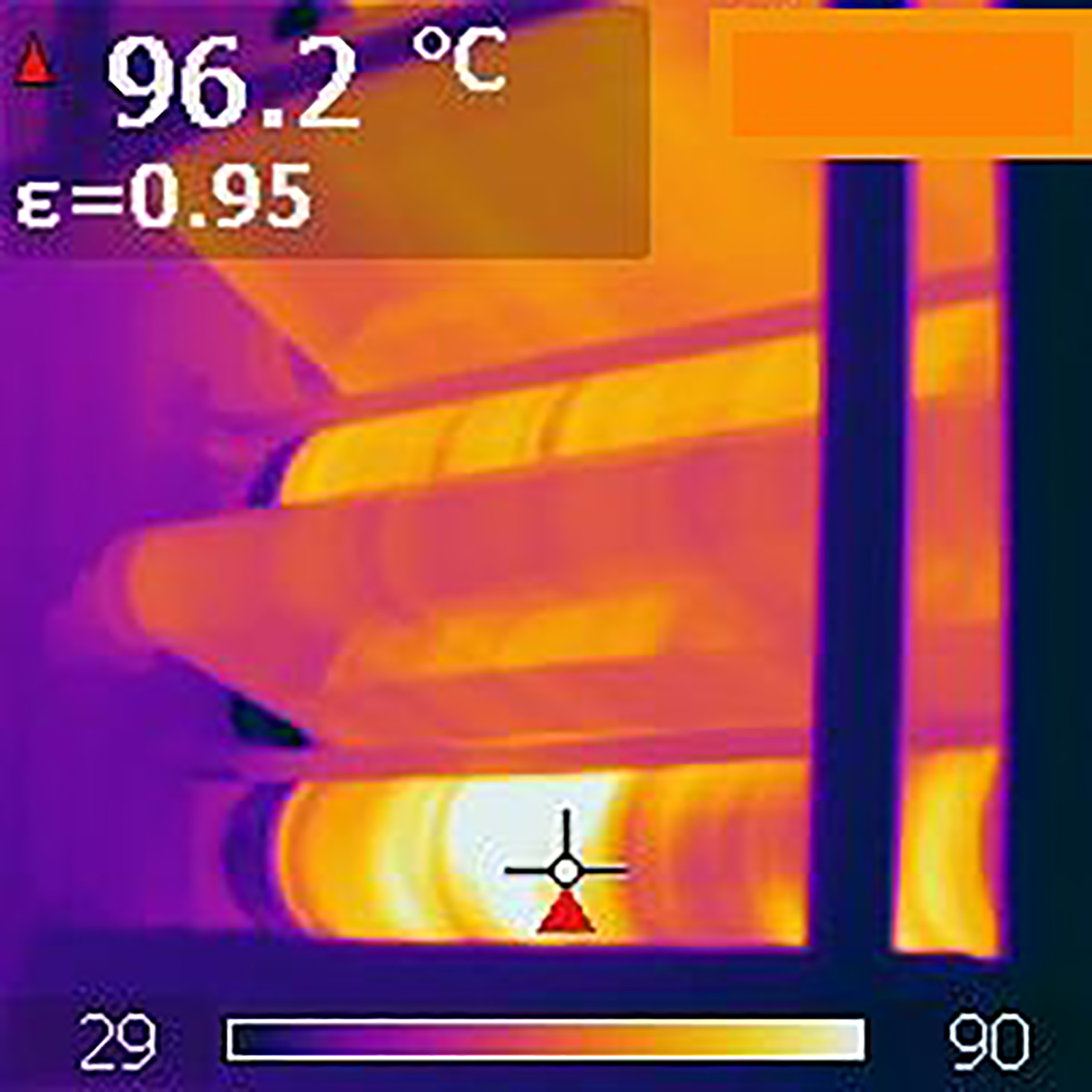

• Geometric checks on site, for example hot profile measurements on Yankee cylinders with the aid of laser technologies

• Thermographic surveys

• Ultrasound checks for the identification of defects

Portable machinery and equipment for carrying out on-site processes are entirely designed and manufactured by RIF.