Contextually to the activities of grinding and coating of cylinders, whether they are suction roll – couch rolls, wet presses and Yankee press rolls, RIF is able to perform a complete maintenance and reconditioning service of the cylinder in all its components, such as suction box, Bearing housings etc.

Suction cylinders generally have a crucial function in the paper sheet production cycle and are usually used in very severe operating conditions, with high workload and speed, but above all they serve to drain a huge amount of water drained from the sheet. , mixed with various types of chemical products, mineral charges, fibers, etc., materials that cause different effects to the various components of the suction cylinder itself such as corrosion, erosion, clogging of the shell holes and inside the internal suction box.

If not subjected to periodic checks and maintenance in all its parts, the malfunctioning or poorly performing suction cylinder can seriously compromise the productivity of the paper machine.

RIF offers complete control and maintenance cycles, at different levels of detail based on the maintenance program of the individual cylinder; the following are the main phases of activity:

Internal Suction Box:

• High pressure cleaning / overall washing

• Checkout and replacement of the nozzles and sealing strips if necessary

• Checkout and restoration of mechanical parts, manometers, vacuometers and pipings

• Optimization/modernization for improvement of performance and lifetime

• Renewal and application of protective and anti-oxidation treatment

Heads and Journals:

• Measurement check of coupling seats with shell and eventual restoration of suitable interference

• Measurement of bearing seats and renewal by means of grinding and / or metal spraying

• Renewal of surfaces and application of protective and anti-oxidation treatment

Bearing Housings and Bearings:

• Assessment of condition of bearings / replacement if necessary

• Checkout of bearing seats and refurbishing if applicable

• Renewal and application of protective and anti-oxidation treatment

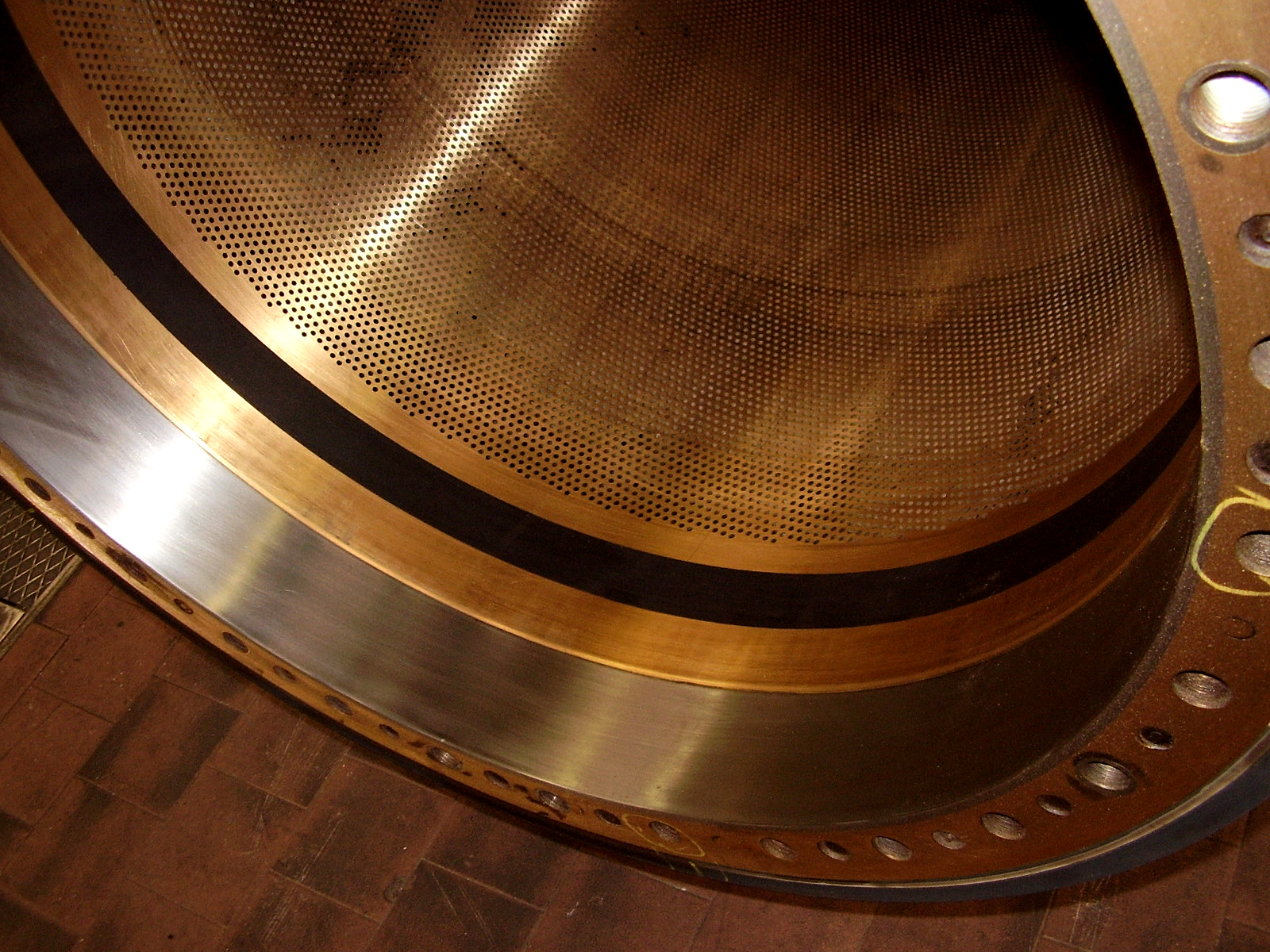

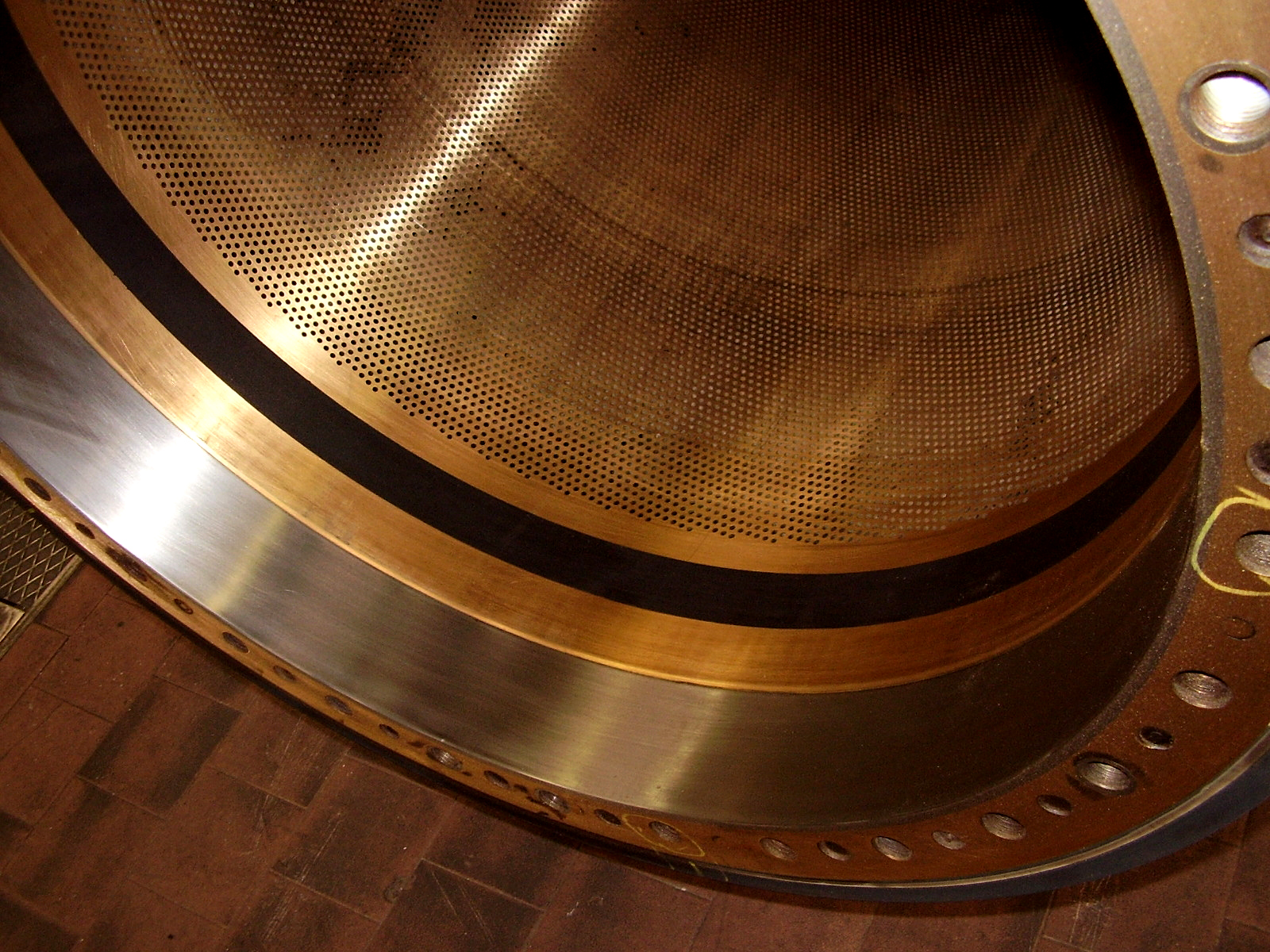

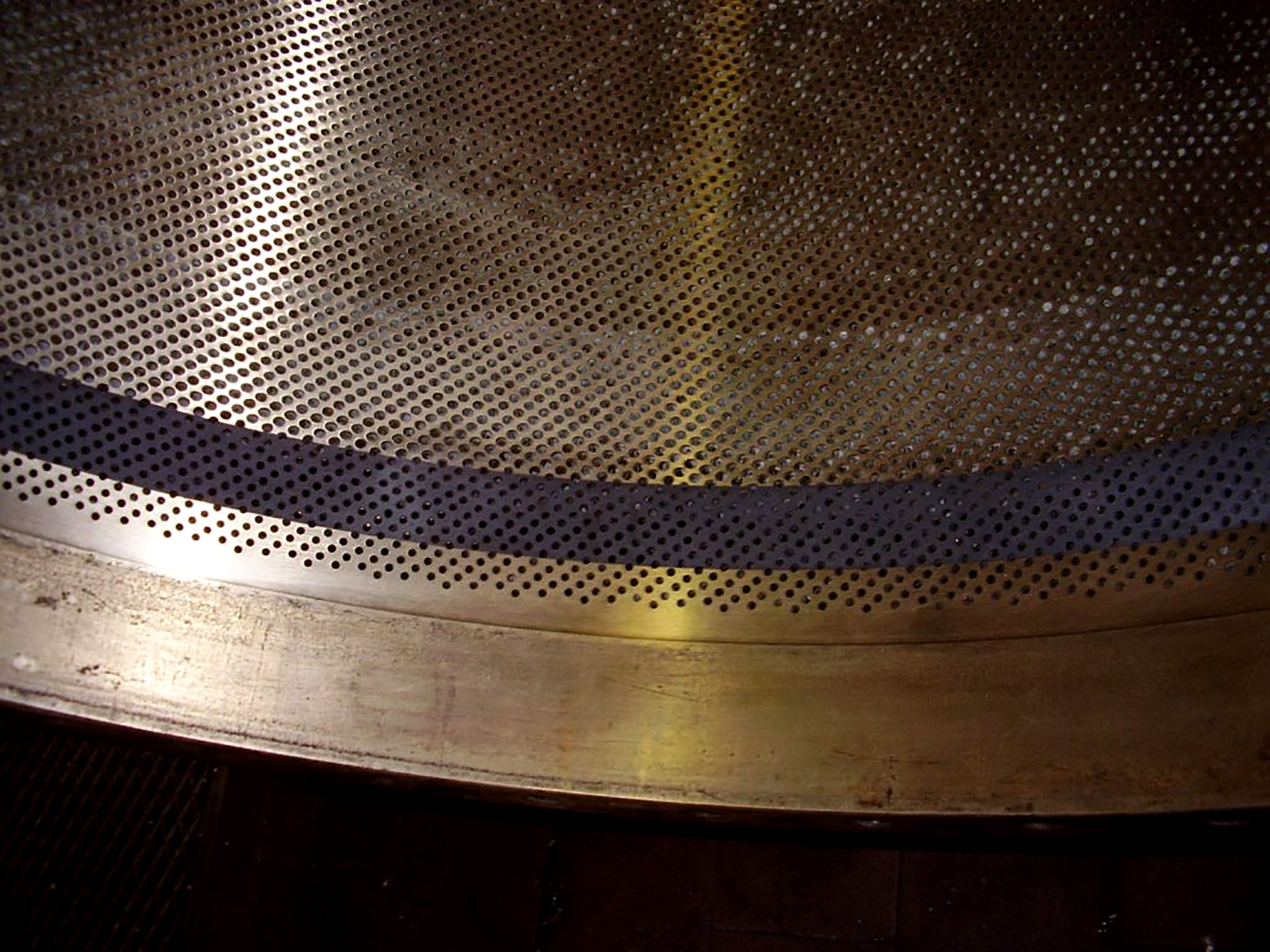

Suction Shell:

• Through holes cleaning by various methods, depending on hardness of deposits

• Measurement of coupling seats, restoration of interference with heads seats

• Assessment of condition of fixing bores and screws/ remachining or replacement

• Repair of damages or indentations on the inside surface

• Inside grinding of shell

Complete Suction Roll:

• Dynamic balancing testing

• Vibration analysis

The dynamic test run of the suction roll is a must to guarantee troublefree performance.