Most of the mechanical processing is carried out in a department strategically located in a central warehouse of the plant.

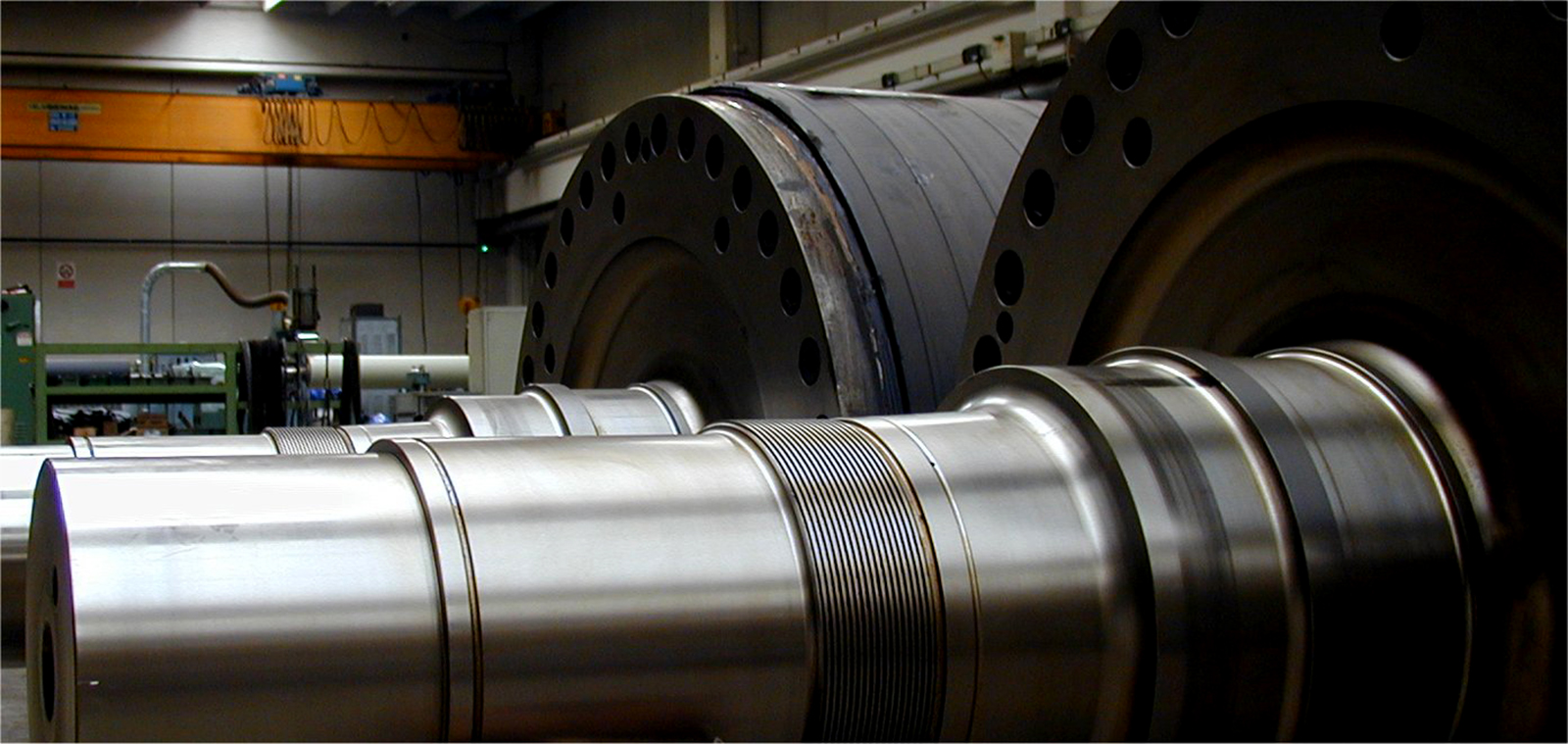

This department plays an essential role in the construction of large cylinders and rotors and also has an important auxiliary function for the other specific production departments of RIF SpA being equipped with the main machine tools including:

CNC Boring Machine for Shells, equipped for internal machining such as:

• Internal grinding of pipes and shells when high stock removal is required

• Internal grinding for suction roll shells

• Internal grinding and honing of swimming rolls

CNC Lathes, for various processes:

• Outside turning of shells, heads and journals for cylinders and rotors for various applications

• Machining of threaded bores

• Roll grooving

• Machining /refurbishing of seats

Dynamic Balancing Machine, for checking and correcting the heads unbalance and controlling dynamic deflection at face center on following workpieces:

• Various press rolls – bearing housings and bearing in assembled/disassembled condition

• Yankee Cylinders or Can Dryers

• Rewinding backing rolls or pope drums

• Various guiding rolls

• Reel spools

• Nip rolls for PVC production

• Rolls for Flame treatment and Corona rolls in the PVC sector

For the manufacturing of new rolls and cylinders, RIF suggests the inside mechanical processing (boring) of the tubes / shells constituting the metal core of the cylinders themselves. This process ensures qualitative and functional advantages for the products, including:

• Uniform thickness with consequent significant increase in critical speed, to the advantage of the life of the cylinder and of the mechanical parts connected to it

• Simplification of the dynamic balancing operation

• Better and more uniform heat exchange in the case of cooling or heated cylinders