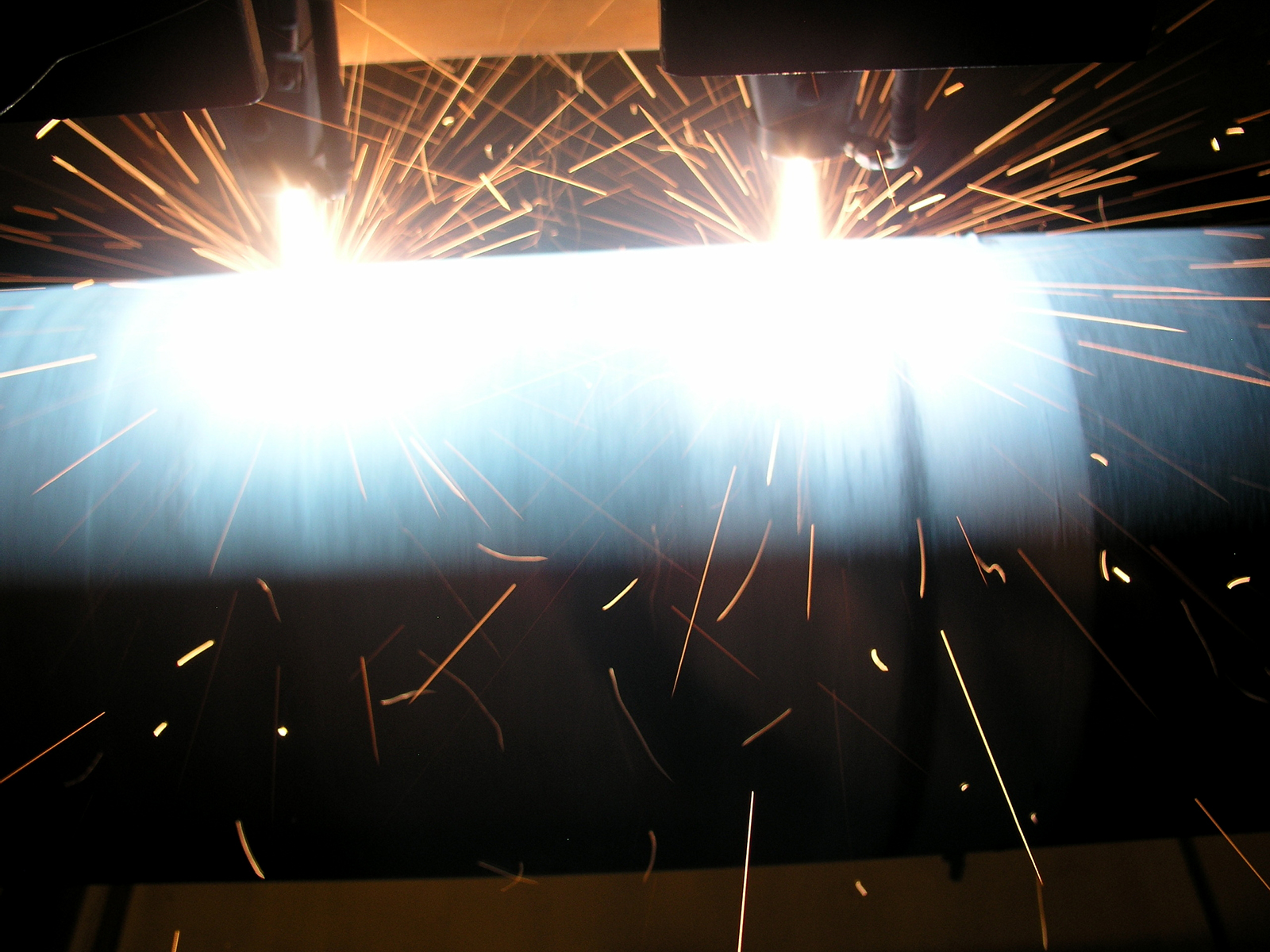

In addition to large cylinder grinding service “on site”, directly at Customer’s plant, which is one of RIF’s most consolidated “core businesses” since the company’s early years, RIF has always been able to perform several types of on-site metallization.

From the year 2000 onwards, RIF has increased its investments in both machinery and research with the aim of becoming one of the leading companies in the world market for this particular type of production, a goal that has been fully achieved both in terms of number of applications and extension of markets sales areas.

The purpose of all metal coatings is essentially twofold: first to preserve the cylinder from downgrading and secondly to obtain surface technological properties, in particular resistance to wear, properties otherwise not achievable by the base metal of the cylinder itself.

RIF now has a range of metal coatings featured by high resistance and reliability, specifically designed for the coating of cylinders which, due to their size and position in the paper machine, cannot be disassembled, in particular:

Yankee Cylinders

Over 450 coatings of the VARIHARD series have already been performed by RIF, with excellent results as regards the above mentioned goals; coatings that have been applied in large numbers both on new Yankee steel cylinders and on existing cast iron cylinders.

Mono Glazing Cylinders MG

New versions of coatings belonging to the VARIHARD series, allow us to perform coatings to be applied on Yankee cylinders for smoothing, where the most important requirements are compactness and low surface roughness.

Can Dryers

The VARIHARD series coatings allow to stabilize the operation of these cylinders, avoiding downgrading or the need for replacement.

Pope Reel Rolls

RIF offers various solutions both with coatings from the REELMET series and with others from the VARIHARD series, depending on conditions and other specific needs.

In case of Pope cylinders equipped with grooves, in addition to metallization, RIF is also able to perform new grooves, directly on the cylinder mounted in line, avoiding to disassemble them for sending to the workshop.

Carrying Cylinders of Rewinders (Rewinder backing rolls)

The elimination of the harmful slipping phenomenon during the final stage of winding the roll of paper is the first benefit resulting from the application of carry-overs of RIF REELMET, whose roughness in version “as sprayed” series promotes the grip against the sheet contextually to the very high abrasion resistance.

Other applications of the On-Site Metallization Service:

• “Spot repair” metallization for the rapid repair of porosity and small surface damage on Yankee cylinders. It is in fact the fastest of all possible repairs

• Localized Metallization or metal coating on worn circumferential bands, for repairing major damage such as deep wear bands, grooves etc.

• Metallization of bearing seats on journals, in particular on Yankee cylinders and Drying cylinders

The metal coatings sector is in fast evolution, both in terms of materials and spraying technologies: RIF keeps pace with this evolutionary progress by testing new versions of coatings aimed at improving their durability and resistance in relation to conditions, operating also in constant increase.

Thanks to a team of specialized and experienced operators and the use of modern as well as versatile machinery and equipment, RIF is able to operate in the field in a short time, also minimizing the inconvenience for the paper mill during the execution of works.